choose timeline

History

Compiled with great care, you can view the history timeline of diving equipment used during these periods. Many of these materials can be admired in our museum.

before Chr.

till

The naked diver

Prehistory

Most man of today do accept that millions of years ago, hairy creatures came out of the trees and walked upright ,and so the human being arises. Herewith the demand for varied food started. Walking along the riverbeds, beaches and rocky coast , he discovered without doubt, all sorts of shells and crustaceans . Different than with the fishing animals ,we can easily accept that the first man made tools, to get all the eatable titbits out of the mysterious sea. That is the way, how he got interested in what was moving and living under the surface. It was no more than a way to survive.

Sponge divers before Christ.

Its known that man living around the Mediterranean Sea, already dived for sponges ,some thousands of years ago. In India and the Pacific, it were the pearls, and in Japan the divers reaped seaweed and crustaceans . To save time the divers descended by using a heavy stone. Later improved with one slope side ,used for steering during the descent.

Glass made it possible, to see before ,if there was something to get on the bottom. The only thing we know about diving glasses or masks in the antiquity is , that fifty years ago ,the Philippine divers used still self made wooden diving goggles, with a very small piece of glass.

In Japan and Greece the profession of diver was a family tradition Those divers did dive ,for many times per day, to more than 20 meters. The average diving time was one and a half minute. It was not exceptional that the diver came back on the surface bleeding out of nose and ears. Also there has been told about the short life of a diver in the old times. In the same time it seems to be that some families have special genes to become a better diver. Famous are the Japanese female divers ,they could dive for a long time and get even very old.

For the salvage of valuables, particular the divers of Rhodes were specialists. Even there has been written about what part they get of the salvaged goods on a certain depth.

Also there has been written about navy divers. Around the Mediterranean Sea ,in that time ,they used navy divers in every war for sabotage. Also the Spanish fleet had those divers permanent on board.

Examples of using divers in the antiquity are:

- Herodotus wrote about a famous diver Syllias.

He was hired by Xerses in 460 bc., to salvage valuables out of Persian wrecks. - Alexander the Great ordered divers to remove barricades during the besiege of Tyre in 333 bc.

- Thucydides did the same at the conquest of Syracuse ,215-212 bc.

from

till

Helmduiker, Leonardo da Vinci, 1452-1519

A leather helmet that is connected with a leather tube for breathing . The tube is fixed with a piece of cork to kept it floating on the surface. The helmet has been provided with pins that should protect the diver against sub-sea monsters. Of course this project has never been put into practice. Leonardo made more of this designs.

Diving-bell. About 1500.

The first real diving-bells were build in about 1500.

The first real diving-bells were build in about 1500.

For a long time, a diving bell, was the only tool that could be used successfully, for different jobs on the bottom. Especially for salvage the diving bell was very useful . When the famous warship Wasa had been wrecked on her maiden-trip, near the harbour of Stockholm, most of her canons were salved by bell-divers. In fact is a diving-bell the same as a Church-bell with air in it, but now they add a system to refresh the air in the bell. If not to deep, they did it with leather hoses and a pair of bellows,kept moving by someone on the surface. Another improvement is to hang a heavy weight under the bell to avoid collapsing of it. Because that is what sometimes happened with former church-bells.

For further information about diving-bells , link in on DIVING BELL in the menu.

from

till

Salvage operation of submerged canons by Diego Ufano. 1628

Diego Ufano designed a plan to save submerged canons. His drawing shows a diver who is wearing a leather cap from had to waist , with a snorkel . This breathing tube was fixed on the helmet and was kept floating bye a pigcs-bladder. Like many of this ideas in this time ,they did know about water-pressure. So the diver could not breath , if he did go deeper than half a meter.

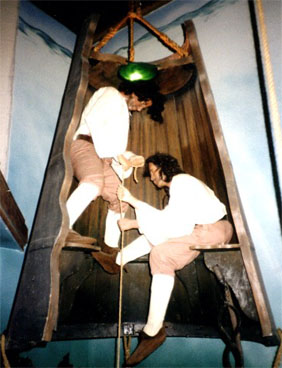

In 1998 the Danish Archaeological Museum made a reconstruction of a mediaeval helmet.

Diving equipment was designed all over the world.

During this centuries, everywhere on educated parts of the world on different times and different places, they designed and made many types of diving- helmets . They used leather and metal.

Giovanni Borelli 1608-1679

May be he was the inventor of the self-contained diving apparatus. He was may be the first one who did understand something about pressure. Borelli equipped his divers with something that looks like an air-bottle with pump . His design unfortunately has never been used.

from

till

John Lethbridge

To salvage a lot of sunken silver, John Leathbridge designed in 1715 a complete new type of diving equipment. It had waterproof leather cuffs, to make it possible to let the divers arms outside of the barrel and pick up the submerged value. Because of the pressure inside, was not the same as on the outside , we can assume that he could not work on a great depth. In spite of this fact ,he did succeed in the salvage of a big treasure of silver.

Klingert`s diving equipment 1797

One of the best diving equipment

One of the best diving equipment of this time, that really had been used . Special is that Klingert knew about water-pressure. He did use some air pump to keep that equal, in and outside the helmet. This German invention has been tried it out in the rivers Oder.

Shalow Water Helmet

The first helmets were very primitive of course, they look like an iron bucket with a window in it. To compensate the floating power of Archimedes, they used some weights fixed on the rim of the bucket. Via a simple leather air-pipe they created an overpressure in this helmet. The air that had been pumped came, for instance , from a pair of bellows like a black-smith normally did use for his fire.

from

till

Brize-Fradin diving equipment 1808

A French inventor who designed some diving-bells as well. This drawing is one of the first of a self-contained diving-dress. In a steel container on his back he carries his air supply. We don’t know if it is ever used.

The Triton by Friederich de Drieberg 1809

The diver gets his air-supply from the surface. A system of rods, connected on the crown, activated the bellows . He has to move his had , fast enough ,to provide himself of a steady air-supply. In his hand he carries a candle- lamp with air supply. This design doesn’t look very usable .

The copper helmet

The industrial revolution offers new materials and techniques. Together with this, and the use of copper and rubber became it possible to manufacture a very useable diving-equipment . Especial the invention of rubber made it possible to fabricate a perfect waterproof suit In this way they could do diving-jobs at 250 feet.

Armoured diving-dress by the Carmagnolle brothers 1882

One of the first, one atmospheric diving-diving equipment, for the greater depth. This heavy gear was patented in Marseille but never been used. In spite of the excellent workmanship, it would have been to much to expect, to keep the big number of joints watertight . The helmet has a big lot of small glasses. You can see this item to-day, in the Naval Museum in Paris.

Rouquayrol-Denayrouze apparatus 1860-1865

By using rubber, he made a watertight suite, with an air cylinder at the back. This reservoir could been kept on 25 till 40 atmospheres ,supplied from the surface via an air-pipe. The air-supply to the mask was regulated by hand and it was the first apparatus of this principle. This system has been used later ,by Cousteau and Gagnan in 1943.

from

till

Siebe Gorman

On both sides of the pump are mounted two, heavy as lead, fly-wheels with four handgrips each. The pump can be used by two divers at the same time and on a different depth till 15 metres. By just one diver it can be used till a depth of 30 meter. The moving parts have to be lubricated regular, by hand. The cylinders itself have to be lubricated by very little oil ,to prevent of leaking oil in the air-pipe where its liable to the rubber lining . If used by one diver, the left air-pipe connection has to be used. When diving on a little depth you can disconnect one of the cylinders (system patented) ,and two man to rotate will be enough than.

The heavy fly-wheels of about 70kg. will guarantee a continuous speed , even when one of the turners is using less of power. This is important, because the weight of the submerged diver, depends on the quantity of supplied air. When the diver is working on a greater depth it can be necessarily to turn the wheels by six man. Of course they have to be relieved after some time ,stopping is impossible.

During pumping for a greater depth or with two divers, the cylinders will generate some heat that has to be cooled , for a hot cylinder has a lower output of air. For that purpose, water-jackets are fitted around the cylinders. The four rings ,on the outside of the pump-case, are used to lash the pump on the deck, with ropes. Otherwise the whole pump will start to walk ,when some strong fellows are turning the wheels. With some experience you can read on the build-in pressure-meters, at what depth the diver is working. To each pump belongs schedules ,on which you can see ,how many turns of the wheels per minute ,are necessary to provide the diver with fresh air on a certain depth. By the ultra-solid and simple construction ,this pump is even after years of standstill, still useable.

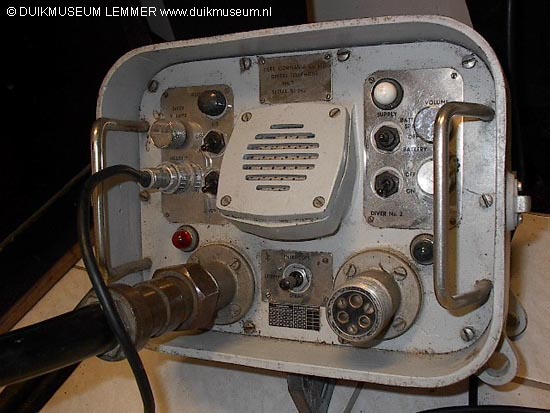

Two-diver telephone (British Admiralty patterns). 1920

There always had been a demand for better communication between the diver and attendant . Particular on greater depth ,and during salvages. The former rope signals did no longer satisfy. During a short period, they tried a sort of stiff rubber speaking-tube , but not for long , it was to much an obstacle for a working diver . The invention of the telephony, offers a new possibility. Electronics were still in its infancy and the amplifier had not yet been invented. Besides of the fact that the former air-pumps did make such a noise in the helmet, that it was not easy to converse. For this reason the divers used different systems like;

- Throat microphones

- Headphones sewed in a kind of linen pilot-caps

- Separate phones and microphones fitted in the top of the helmet.

The big plugs connecting the telephone cable and helmet, are looking absurd to-day (especially when you have to open it) ,but in that time the manufacture of an waterproof electric plug, was an enormous performance

Due to the high use of electricity of this apparatus, the batteries are not capable enough to keep a continual contact with the diver. When the diver wants to speak, he has to press his chin-contact to call attention . Then a bell starts ringing on the surface , after that , the attendant can make the connection. If used by two divers ,for the other one there is a buzzer.

The attendant also can make a connection between the two divers . It is also possible to separate this conversation ,so that nobody on the surface can hear it. The communication-set has been build in ,a teak-wooden case.

Siebe Gorman `s standard closed-dress

Siebe Gorman `s standard closed-dress with 12 bolt helmet 1940 Since 1837 Siebe started to develop a closed dress . This type of diving equipment meant a break-through in the divers-world. For the first time in history the diver could get dressed on a easy way and work safe and comfortable on the bottom ,for a nearly an unlimited time. The temperature and the supply of fresh air became herewith under control. By the excellent worked-out ballast-system, it was possible to walk on the bottom ,almost like normal. Even the diver could regulate his own weight, and even make himself afloat for a job on a ships-propeller.

Inlet-valve

Inside the air-tube connection, on the helmet , there is a perfect closing non-return valve. This is very important! When this valve is missing ,or doesn’t work proper, the diver could be squeezed into his helmet in case of stop pumping for a longer period ,or a broken or disconnected air-pipe. Even on a depth of 3 meters this can be fatal.

Outlet valve

With a notched hand wheel on the outside of the helmet ,the diver can regulate the air pressure in his suit, and in the same time his weight on the bottom, and the balance between in – and outgoing air. For a quick release of air, inside the helmet , there is a sort of copper button just above the right ear. If the diver wants to drain some extra air ( to become heavier ), he has to press this with his head. In that way he can do this without using his hands or disturbing his former adjustment of the valve. It’s also possible to close the outgoing air completely, to reduce the noise during conversation or quick ascend . For this reason in the middle of the outside hand-wheel, there is a little nipple, easy to push by the cold hands of a diver in wintertime. Connected to this valve on the outside, they fixed a smart system, to protect the diver against the possible leaking-water. This water is collecting in a little room and will disappear together with the regular outflow. The good use of this valve is a must for the easy handling use of this equipment.

Submarine-escape equipment. 1940

American based on the rebreather system.

Front tap

Almost mentioned as spitcock.

Its principal use is to enable the diver to suck a mouthful of water with witch he can remove condensation from his window. Its unknown if its ever has been used in that way. Even the manufacturer is not sure about that. Its for sure; the diver should have a sort of goose-neck or very long lips to suck on it. Siebe Gorman however used this tap, in one of his experimental tanks in England , to take samples of air for investigation.

Drager smoke-rebreather 1950

This system was the first type of a self-contained breathing equipment. It works with oxygen on the re-breath principle. Steel bottles for more than 30 atmosphere could not be made this days, in such a way the use of pure oxygen with re-breathing system was the best possibility. After using this system and a nearly death of the diver in 1882, there was almost no demand for this system. Only the fire-brigade did use it in smoky circumstances. In spite of this, they developed during world-war 1 a good working system for underwater. With a bottle of 150 atm.and a CO2 absorbent-chamber, this system has been used for sub-marine escape, sabotage, human-torpedo and other navy-applies.

The system exposed, has a full face mask, in- and out breathing hose, high-and low pressure- reducer, a CO2 absorber and of course a bottle for oxygen.

Umbilical diving- gear of Drager. Year 1950 -1974

Six bolt standard diving suit of Siebe Gorman. Ca. 1955

This diving gear has been used by the diving- and salvage company Goedkoop-Bros, at Amsterdam . At that time they had six of this outfits in use . This very popular diving outfit was world-wide known as the standard diving equipment. It has the following parts.

- Leather shoes with wooden inner-soles, and outside soles of lead. Its weight is 8 kg each.

- The diver wears a belt of very strong leather and on it, and in a sheath , a special Siebe-Gorman divers knife. To prevent this knife of falling out ,when the diver is going upside-down, in the sheath there is mounted a flat spring by which the knife is jammed a little bit.

- The front and the back weights are made of solid lead with a weight of 18 kilo each. They have been hanged on the helmet and corselet, have been connected with a leather belt ,between the legs. This belt will prevent against floating off of the helmet, from the divers shoulders by expanding air ,when he is coming up to fast.

- The suit itself, is made of two layers special woven canvas, named twill. Between this two layers there is a thin layer of natural rubber.

- The cuffs are also made of natural rubber and are fabricated in only one, big size. To enter the stiff cuffs most divers did to use liquid-soap. The divers with smaller wrists had to use special rubber wrist-rings. If, even that ,was not sufficient ,the student-diver had been advised to cancel his plans. With small wrists like that ,he shouldn’t be strong enough to become a good diver.

- The rubber collar of this type of suit ,has a very large entry , the six holes in it are corresponding with the bolts of the helmet-corselet.

In this period, helmets have been made with, zero till 12 bolts

But the six bolt type was the most successful one in history, it is used and copied world-wide. This diving-equipment made it possible to bring a diver ,safe ,dry and comfortable ,under water in some minutes . The intelligent and simple construction ,made it possible to do the maintenance by the diver himself ,eventually with the help of a local copper-smith. On the surface the standard diving equipment does not look as useful, as a modern one. But ,once on the bottom , the experienced diver can do a fine job. As a difference to modern diving gear ,a diver can give himself some weight . That makes it possible to walk and push and pull ,without floating away like an astronaut.

In the sheath a sort of flat spring has been mounted , the knife is fixed now against falling out when the diver is going upside down. The back and front lead weight are each 40 lbs.( 18kg)

GKS 3 M, Russian 3 bolt helium helmet. ’55 – ’82

English Standard-diving outfit 6 bolt, with front weight /bale-out air supply, Siebe Gorman & Co LTD. ’50 ’70

English Standard-diving suit 12 bouts, Siebe Gorman & Co LTD.1940 – 1970

from

till

Russian three-bolt helmet from 1960

The Russian Three-bolt helmet with telephone connection has a grip on top and a front glass for welding. The air-outlet on the right side is not adjustable. The diver is therefore is not capable to adjust his weight under water. In that way, this has to be ruled by the man on the pump.

Russian standard equipment UVS 50 M ±1960

The operation of this Russian standard diving equipment is the same, as that for Siebe Gorman`s. Front and back-weights ,lead-shoes and a simple adjustable air-outlet. Only the helmet and the connection on the suit are a little different. By the way the Russians have been inspirited (just like all the German manufacturers) by the French Denayrouze helmets , those where namely the first three-bolt helmets. The German firm ‘Ludwig von Bremen’, (later named Hagenuk), obtained a licence of Denayrouze to build his helmets. The Russian also used Denayrouze helmets ,and started to copy them ( so far we know without permission), about 1900. After some years, the model of the helmets has been changed a little bit. The shape of it became more and more like Siebe Gorman’s. The model of this Russian helmet, seen on the picture, did develop during world-war 2 and is still building and used. Different of the Siebe-Gorman system ,the diver has to wriggle himself ,via the narrow collar, into his suit.

To make entrance a bit wider the helpers do need a special build apparatus, working on pressured air . Or… 3 à 4 strong man. When the diver finally is dressed with his suit and corselet, they have to pull the rubber collar trough the narrow space between the divers neck and the copper corselet. With tree bolts and the rubber collar between, the helmet can be mounted waterproof, on the corselet. The grip on top is useful to carry the helmet. If you can hoist safely a full dressed diver on, must be disputable. As you can see by yourself, the Russian are not very interested in beauty in this sort of things.

Siebe Gorman 6 bolt helmet. 1960

Special made for the Dutch Navy.

This type of standard equipment was been used by the Dutch Royal Navy. Different on this helmet are the modifications, special made for the Dutch Navy. Extra are the second front glass on top, and a breast-weight where-in two small air bottles as a bale- out which are connected with the corselet. Also the two weight-studs , on the front of the corselet, had been exchanged by four eyes . On this studs you can hang , the front and back-weight separate, with musketon-hooks. On the small front-eyes on top, you can see two lines wherewith the air-pipe and life-line has to be tied up. Upon the back-side ,we will see a small hinged stop-pin ,intended to have to be engaged in a recess at the back of the corselet . This is the position, the helmet/corselet thread ,has been used optimal. The stop-pin will also prevent the helmet against unscrewing by accident. In that position the helmet has to turn as heavily over the leather seal ,that it is nearly impossible to bring the stop-pin between the mentioned recess . On the rim below , on both sides of the helmet , you will see a hook that is used to put the weight -ropes through it , as an extra safety to prevent of losing the helmet.(not the navy model) With this system the diver had the possibility to undo himself of both of his weights ,and to float to the surface , in case of air-pipe problems . Even he can save himself by cutting his own air-pipe, when it has been jammed somewhere. By using four hooks and eyes instead ,like the Dutch navy does ,this option could not be used any longer.

Bale-out breast-weight

As a substitute for this, they did use a breast-weight with two little air-bottles of 1,2 l each, imbedded in it. Via a connection- hose ,with non-return valve connected with the corselet, the diver has the possibility to make himself afloat by opening the bottles. To create the same weight as the original breast-weight , they have to make the hole thing of cast-iron, and of course it has to be bigger . The manufacturing of this bale-out was a unique co- operation between the two competitors, Drager and Siebe- Gorman. The bale-out air-breast weight was made by Drager and the connection on the corselet by Siebe-Gorman himself. The civilian diver did not use this system, because it was to big , and reduced the freedom of movement during his work.

Shoulder pad or helmet cushion Shoulder pad or helmet cushion.

With an experienced team you can dress a standard-diver within some minutes. It has to be the intention, that a diver for the time he is on the surface , has to carry the heavy load of his outfit as short as possible. Once in the water ,the buoyancy will eliminate this. If trimmed well ,he even should not feel his helmet and weights any more. But, if there is a change that the diver has to wait to long on the deck, or if he has to make many short dives, his shoulders will get injured. Special for a situation like this, Siebe made a sort of shoulder-ring-cushion.

The “standard” diving equipment.

Before they could use rubber ,it was not possible to dress a diver waterproof in a way that he could do a good job on the bottom. The first fully waterproof suits has been made of two layers of special woven canvas named twill, with a layer of nature rubber between. The suit has a double collar . The outside collar was made of vulcanised rubber, that fits on the corselet and around the bolts mounted on it. The inner collar , made of the same material as the suit , keeps the possible leaking water away of the divers cloth. The cuffs are also made of vulcanised Hevea rubber and has to fit waterproof on the divers wrists.

Divers air-pipe.

The air-pipes are available in floating (red) and sinking ( black) performance. They were made by hand in lengths of 15 meter with solid copper couplings . Vulcanised in the rubber of the air-pipe, there is a steel spring to prevent against kinks . If there is a kink, caused by force, it can be fixed with a hammer.

Telephone-cable

The rubber telephone-cables had to be made by hand also. Inside the cable , there are four electric wires and a phosphor-bronze heart. This heart is strong enough to hoist a full dressed diver out of the water. Phosphor-bronze was in that time the best material to make a strong rust-proof cable. The big connectors were revolutionary in those days, but nowadays they do look ridiculous.

Divers telephone ,Mark VII Siebe Gorman ca. 1960.

A very solid loud-speaking telephone for helmet-divers that had been used all over the world. The apparatus is build in a cast-aluminium case with a waterproof lid . Its hardly to damage and it can float. The telephone can be used by two divers in the same time , for communication with the surface ,or among themselves. The connections had to be made on the surface by switches, or by the divers themselves with a chin-switch inside of the helmet.

Het P-long. 1960

This lung has been manufactured by the firm Dunlop. It was especial made for the Navy of the Western world . The breathing gas was pure oxygen and the system was that of a oxygen-re-breather ;What means that the breathed-out oxygen had been breathed-in again, after filtering. The P means Port. It was used by the frog-man to do jobs in the harbour on Navy-vessels.

The SDDE. Begin of 60

This set has a two bottles of 4 litre with compressed air , a back-pack and a sort of envelope wherein 10 slices of lead, possible to drop. This set has to be used with an umbilical for air supply from the surface . With a full-face mask and a two large breathing-tubes from the demand regulator , this set had been used as a diving outfit of the English Navy ,to do jobs in the harbour underneath ships submarines etc. The two bottles are mend as a bale out. Manufacturer of this set is the firm of Avon in Great- Britain.

The Dive Save One , ca. 1960

The Dive Save One is a diving set that is been compounded of three , 5 litre air bottles, connected by an air-tube. Between bottle one and two there is a breathing-reducer mounted; The famous egg of the Dutch firm Loos & Co . It has in- and outgoing breathing pipes of a different length to compensate the a-symmetry of the construction. To carry the set ,it has been provided with two steel straps who fit around the divers shoulders. On each strap, there is a piece of lead of 4 kilo, mounted by a quick release system. To compensate the negative buoyancy of the whole thing ,the manufacturer has mounted two floats on the backside . In this way, set can float again when the lead-weights has been released. The shoulder-straps are made of solid steel , and it is could be possible , that if the diver should fall or jump with this set on ,he would break his collar-bones This did happen sometimes.

There is a story about Navy-divers who dropped or lost their lead-weights to often. This became to expensive ,so they tided up the front- weights with a rope of one meter length. In this way the diver always be able to find his ballast again. Of course in a real case of emergency ,the water should not be deeper as one meter. This diving-set has been used in combination with a full- face mask.

Development of the Dive Save series.

This type of demand-breathing-regulator had been developed in 1955 by Jan van Buuren. For him and his son it was a sort of life time job. Based on experiments , with their test-types ,they perfected it. The employees of the firm Loos & Co , from Amsterdam were very interested in it and visited him at his laboratory, to do experiments for quality and durability. Of course Jan van Buuren and his son were very tensed when their apparatus had been tested by the Royal Dutch Navy `s lieutenant Huiskens and his man.

from

till

NEMBA

Netherlands Mixed gas Breathing Apparatus. Used from the beginning of 1970. Special made for the Royal Dutch Navy and also developed by them ,after which it was manufactured by Siebe Gorman in London. The whole set is non-magnetic and non acoustic. This diving-outfit is made for jobs on mines, in and around harbours, and of course on see. This breathing-system is of the of semi-closed system. The benefits in the use of it are; Easy maintenance, maximum diving-time with the chosen breathing-gas , low breathing resistance and dive-medical safe. The total weight on the surface, ready to use ,is 37 kilo and in the water about 4 kg. Its is a nitrox set that can be used for the gas- mixes of B60/40%, C 40/60% and D32,5/67,5%.. Because of the set has a very stiff in- and out-breathing tube , the divers-mask has the inclination to stay straight ahead, when the diver is looking to the left or right .

Diver with a compressed air set

type Loos & Co ca. 1970.

This set has been used mainly, by the Royal Dutch Navy around 1970-1980. It has been composed of two compressed-air bottles of 8 litres each, and has a build-in breathing-reducer ,made by Jan van Buuren .The air has been reduced in two stages; In that time named by the Dutch Navy as, reducing-valve (first-stage) and breathing-automation (second stage). Build-in the first stage, there is a bale-out valve . The diving-mask belonging to this set, should only be used in combination with a nose-clip. On the picture you will see a diver wearing P-boots. In this boots ,you can place various lead-inlay soles ,intended to stay firm on the bottom and walk on it.

Dutch Royal Forces Constant Volume (CV) suit., Drager & Viking. 1979-1999.

Deep-diver with SVG 200 B with IDA – 72 SCCR 200m ’70 – ’80.

Dutch Marine Frogman LAR III (3), Drager. ’75 – ’82

Russian battle-diver IDA – 71 CCR, O2 20m, nitrox 40meter. ’70 – ’80

Offshore diver, Kirby Morgan Superlite 17a, DSI. ’80 – ’90

CDBA Clearance Divers Breathing Apparatus, Avon ’70 – ’00

from

till

today

Dutch sport diver ,Mares 2004

TEC Sport-diver > 80m, O2, nitrox and helium, various manufacturers 2000 – 2004